-

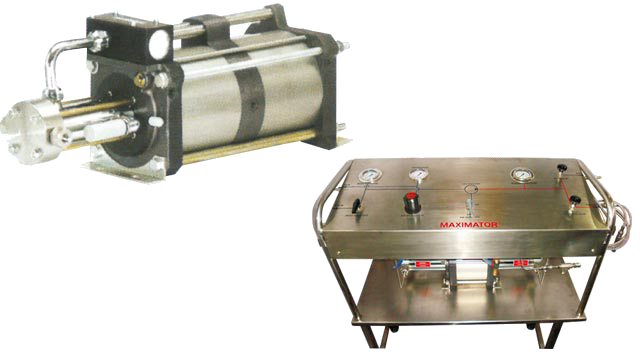

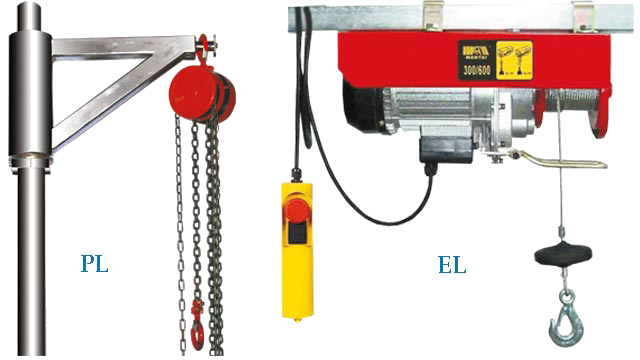

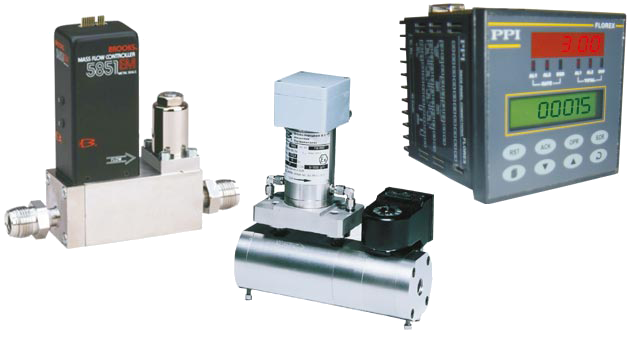

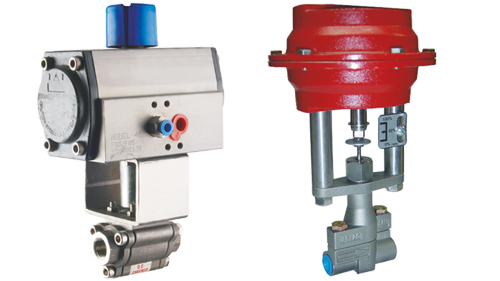

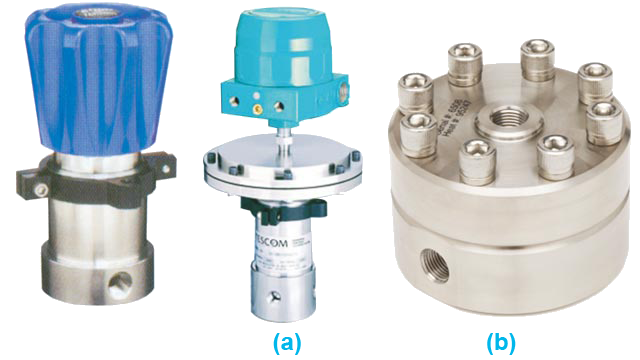

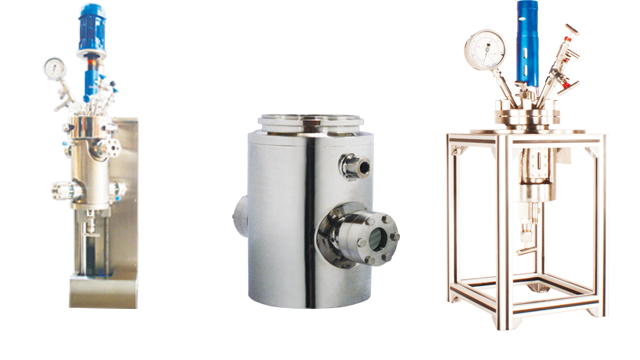

Products and Solutions

Efficient and reliable products for all your unique requirements.

-

Support & Services

We offer services that prioritize customer satisfaction at every step.

- Partners

- Industries

-

About Us

Ask us on Social Media Use our social channels to search for answers and ask questions

- Blogs